What is 3D printing and how is it don?

-

Jun, 13 2023

-

0 Comments

An Introduction to 3D Printing

3D printing, also known as additive manufacturing, is a revolutionary technology that has gained significant popularity in recent years. It allows us to create three-dimensional objects by layering materials on top of one another. In this article, we will explore what 3D printing is, how it works, and its numerous applications. So, let's dive right in and learn more about this fascinating world!

The Science Behind 3D Printing

At its core, 3D printing is a process that transforms digital designs into physical objects. It all starts with a digital file, typically created using computer-aided design (CAD) software. This file is then converted into a series of thin layers, which are used as a blueprint for the 3D printer. The printer itself works by depositing material, such as plastic or metal, layer by layer until the final object is formed. This method allows for incredible precision and customization, making it perfect for a wide range of applications.

Types of 3D Printing Technologies

There are several types of 3D printing technologies available today, each with its own unique set of advantages and limitations. Some of the most common methods include:

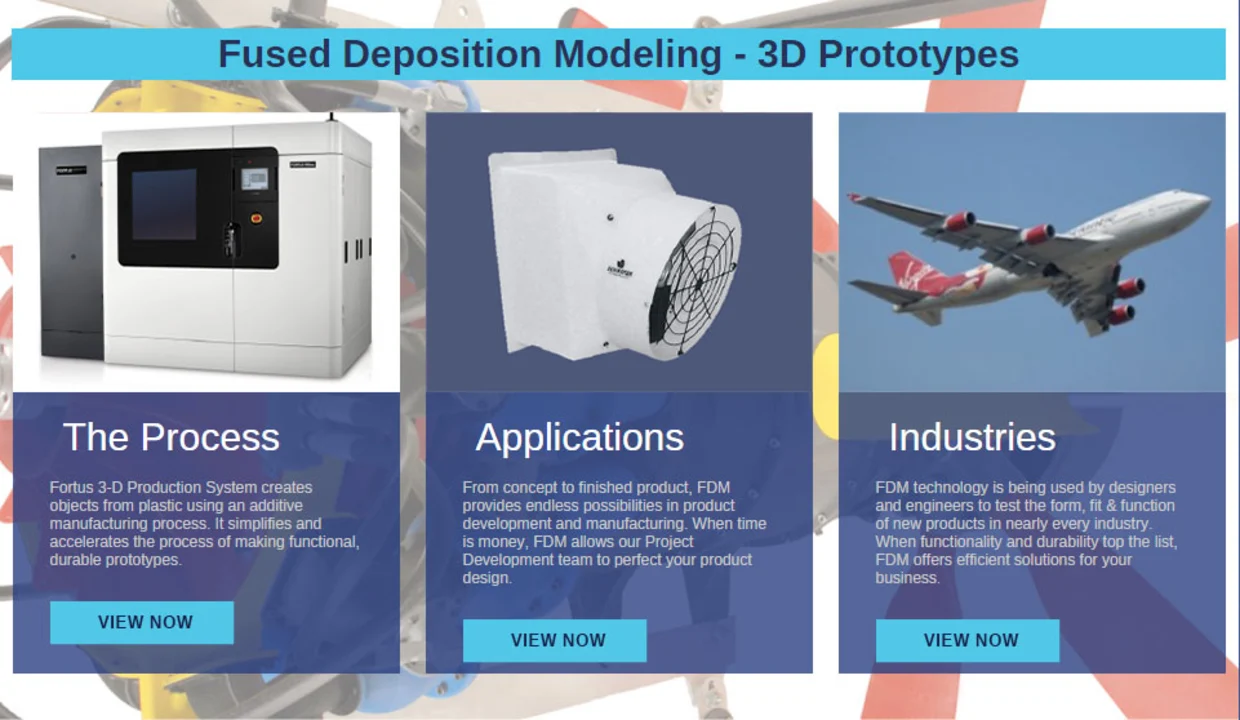

Fused Deposition Modeling (FDM)

FDM is the most widely used 3D printing technology and is known for its affordability and accessibility. It works by heating and extruding a thermoplastic filament, which is then deposited layer by layer to create the object. This method is ideal for creating prototypes, functional parts, and even complex geometries.

Stereolithography (SLA)

SLA is a form of 3D printing that uses a laser to cure liquid resin into solid layers. This process results in extremely high-resolution objects with smooth surfaces and intricate details. SLA is often used for creating highly detailed prototypes, molds, and even jewelry.

Selective Laser Sintering (SLS)

SLS uses a high-powered laser to sinter powdered materials, such as nylon or metal, into solid layers. This method is particularly useful for creating strong, durable objects with complex geometries that would be difficult to achieve with other methods.

The 3D Printing Process: From Design to Finished Product

The process of 3D printing can be broken down into several key steps. First, a digital design is created using CAD software or by scanning an existing object. This design is then converted into a format that can be read by the 3D printer, typically through a process called slicing. The sliced design is then sent to the 3D printer, which builds the object layer by layer. Once the printing is complete, any necessary post-processing, such as support removal or surface finishing, is performed to finalize the object.

Materials Used in 3D Printing

3D printing can be done using a wide variety of materials, depending on the technology and the desired outcome. Some of the most common materials include:

- Plastics, such as ABS, PLA, and PETG, which are popular for their affordability and versatility.

- Resins, which offer high-resolution and smooth surface finishes.

- Nylon, a durable and flexible material often used in SLS printing.

- Metal, such as stainless steel, aluminum, and titanium, which can be used in various industrial applications.

Benefits of 3D Printing

There are numerous benefits to using 3D printing, including:

- Customization: With 3D printing, it is possible to create unique, one-of-a-kind items tailored to specific needs or preferences.

- Complexity: 3D printing allows for the production of intricate and complex designs that may be difficult or impossible to create using traditional manufacturing methods.

- Speed: 3D printing can significantly reduce the time it takes to produce an item, from weeks or months to just a few hours or days.

- Cost: 3D printing can be more cost-effective than traditional manufacturing methods, particularly for small production runs or highly customized items.

Common Applications of 3D Printing

3D printing has a wide range of applications across various industries, such as:

- Prototyping: 3D printing allows companies to quickly and affordably create prototypes for product development and testing.

- Manufacturing: 3D printing can be used to produce functional parts, reducing the need for expensive tooling and molds.

- Medical: 3D printing has been used to create customized medical devices, such as hearing aids and prosthetics, as well as for producing patient-specific surgical models.

- Art and Design: 3D printing enables artists and designers to create intricate and unique pieces that may not be possible with traditional methods.

- Education: 3D printing is an invaluable tool for teaching concepts related to science, technology, engineering, and math (STEM).

Challenges and Limitations of 3D Printing

While 3D printing has numerous benefits, there are also some challenges and limitations to consider:

- Material limitations: Some 3D printing technologies are limited in the types of materials they can use, which may restrict their applications.

- Size restrictions: The size of the object that can be printed is often limited by the size of the printer's build platform.

- Post-processing: Many 3D printed objects require additional post-processing steps, such as support removal or surface finishing, which can be time-consuming and labor-intensive.

- Accuracy and surface finish: The level of detail and surface finish achievable with 3D printing can vary depending on the technology and materials used.

The Future of 3D Printing

As 3D printing technology continues to advance, we can expect to see even more exciting developments and applications in the future. From bioprinting and the creation of human tissues, to the construction of entire buildings using large-scale 3D printers, the possibilities are truly endless. As we move forward, 3D printing will undoubtedly play a significant role in shaping our world and revolutionizing the way we create and produce objects.